Introduction

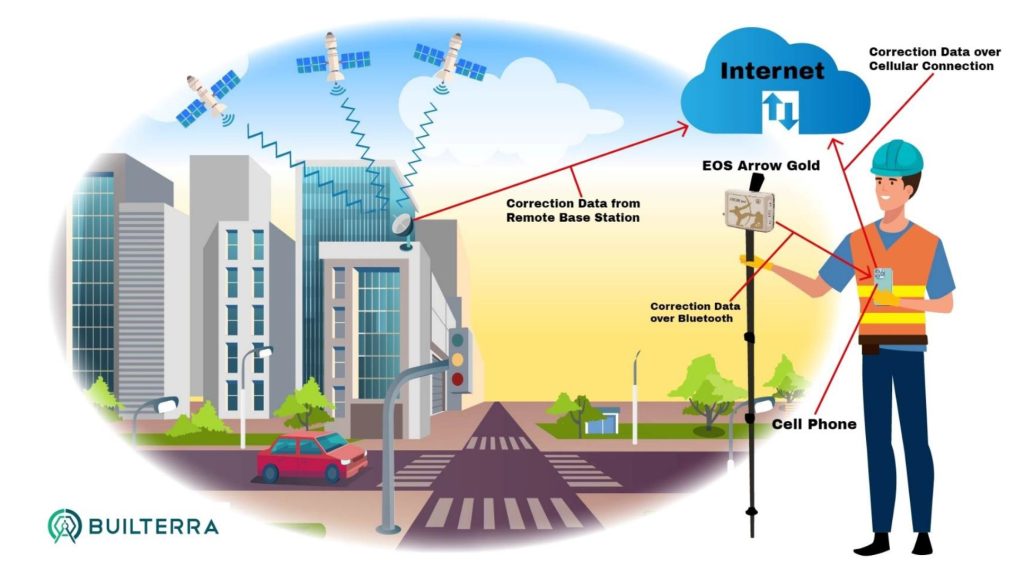

Builterra offers high-accuracy GNSS positioning solution tailored for civil engineering and construction sectors through the EOS Arrow Gold GNSS Receiver and Real-Time Kinematic (RTK) technology. This combination delivers decimeter-level precision in real-time, with a base station providing correctional signals to a rover receiver for enhanced positional accuracy. It's a robust solution optimized for tasks that require precise location data, such as mapping and control in location-critical applications.

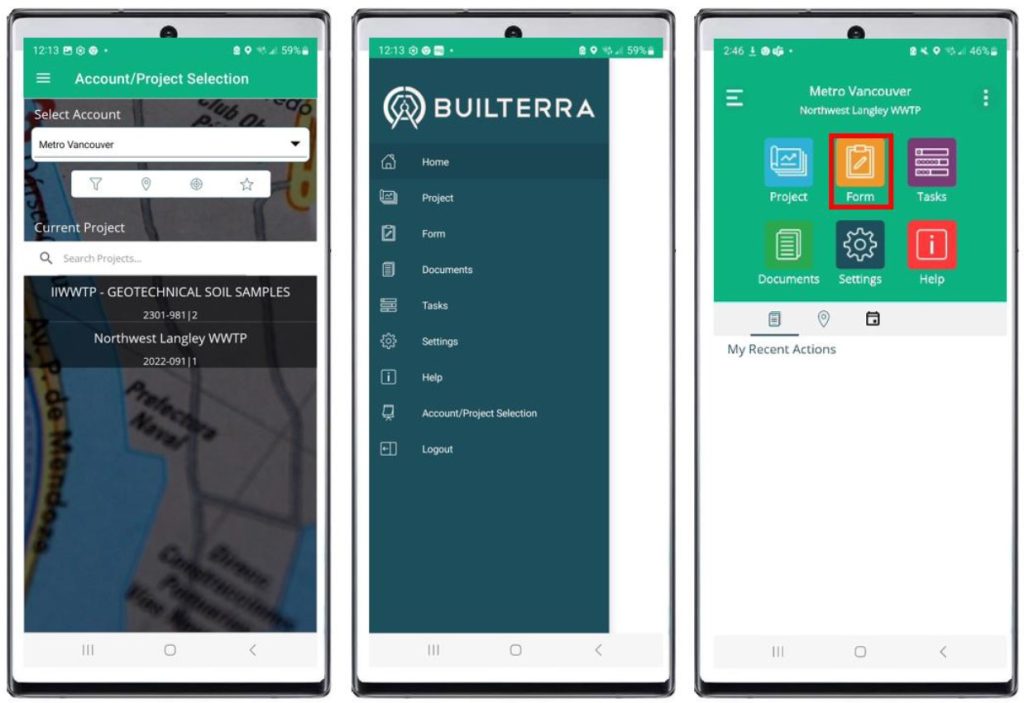

Integration of GNSS Hardware with the Builterra Mobile App

The Builterra mobile app acts as a dynamic data collection tool when integrated with an RTK GNSS antenna, offering unparalleled sub-decimeter horizontal positioning directly on a standard cell phone. Through seamless Bluetooth connectivity, the app syncs with the GNSS antenna to provide users with real-time, highly accurate location data. This integration is crucial for construction and surveying professionals, delivering a portable and cost-effective solution for precision horizontal positioning. The seamless Bluetooth link ensures the phone consistently receives accurate positioning data. This technology enables professionals to refine their workflows, boost project efficiency, and base decisions on reliable, accurate data from the Builterra app.

About EOS Positioning and the Arrow Gold GNSS

One of the notable features of the EOS Arrow Gold is its compatibility with mobile devices such as smartphones and tablets. Through Bluetooth connectivity, the receiver seamlessly integrates with mobile applications, providing a user-friendly interface for data collection in fields like surveying, mapping, and construction.

The Arrow Gold's versatility extends to its ability to connect to RTK networks, enhancing its accuracy and reliability.

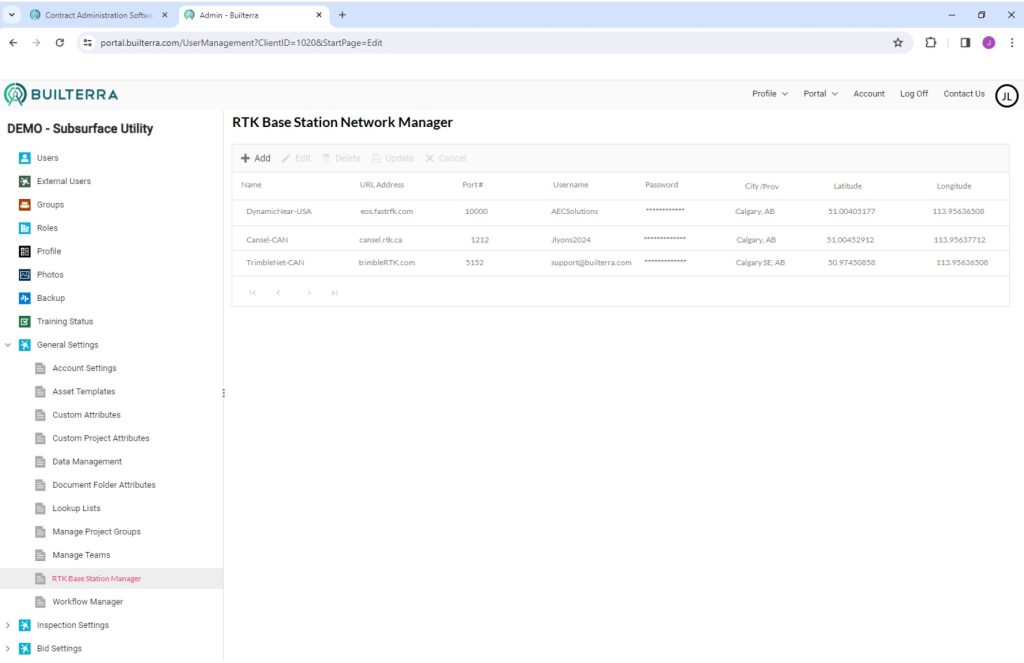

Leveraging the Builterra Project to Manage RTK Correction Sources

Builterra's online "Project" feature streamlines precise positioning by integrating a standardized projection system with a select list of RTK Correction sources.

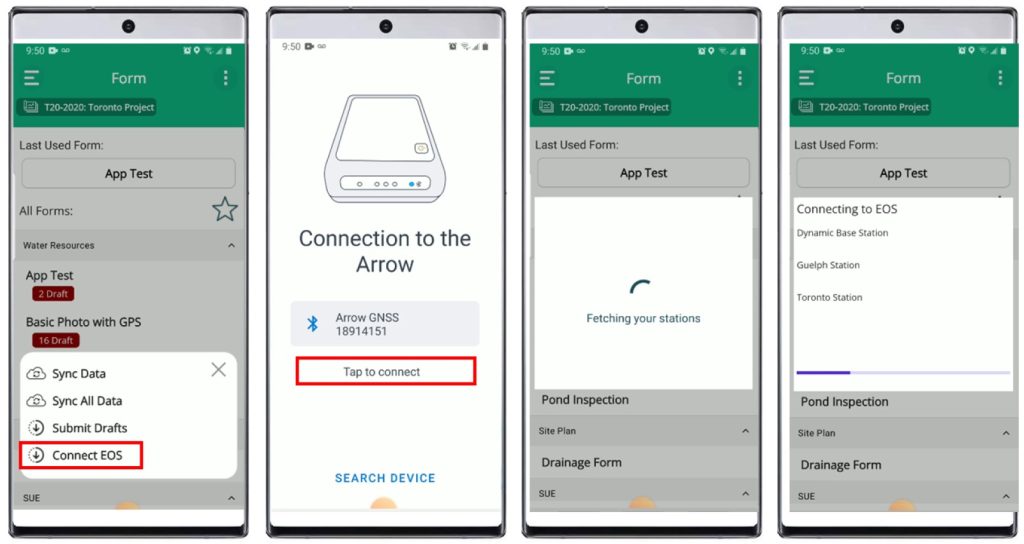

Linking with the EOS Arrow Gold GNSS Receiver through the app, users can easily access RTK networks. The "high accuracy" mode—engaged with a tap—overrides the mobile device's less precise data with the high-accuracy readings from EOS.

Integrated Builterra App & the EOS Arrow Gold GNSS RTK Connection Process

The EOS Positioning Arrow Gold GNSS Receiver stands out as a high-precision Global Navigation Satellite System (GNSS) device designed for accurate location data in various applications.

RTK Base Station Manager

Upon starting an Inspection, the RTK Correction Source is automatically determined by the Builterra Project and setup by the Builterra Account Administration. The Builterra app will display the positioning Status and level of positioning accuracy achieved. All meta-data will be saved to the inspection record for review and reporting.

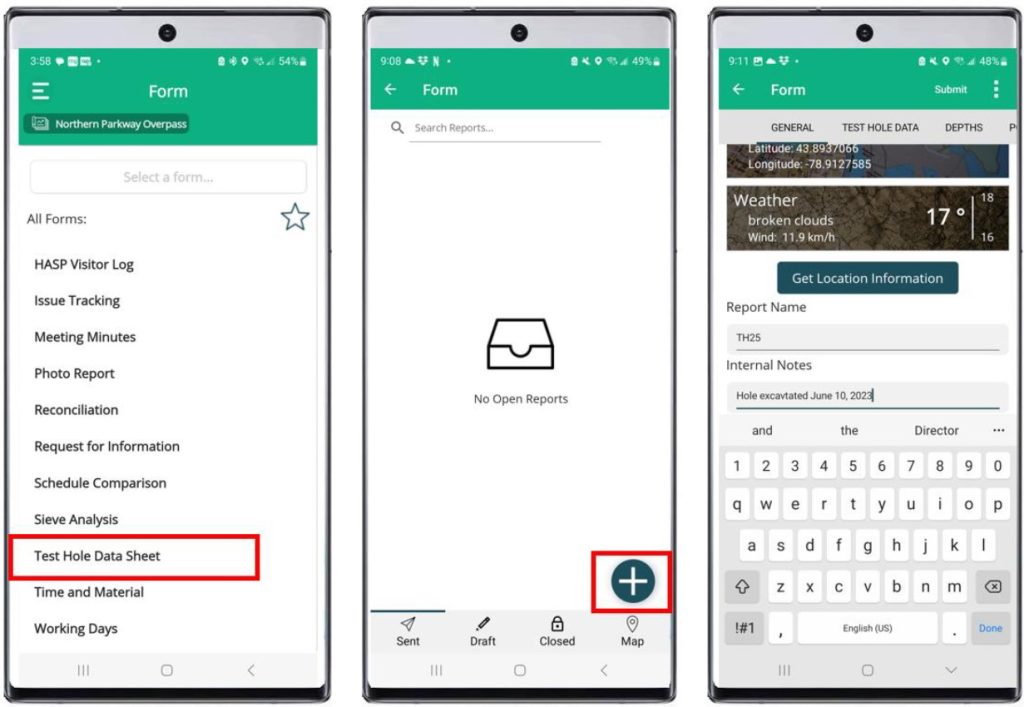

Data Collection Options using High Accuracy Mode

1. Single Location Inspection Records: Leverage GNSS High Accuracy mode to capture a precise location for individual parent inspection records, such as test holes, structures, or boreholes. This method ensures that each record is associated with an accurately mapped point, providing a comprehensive and reliable spatial context for the specific inspection. The high accuracy mode maximizes the usability of location data, contributing to more informed decision-making and precise record-keeping.

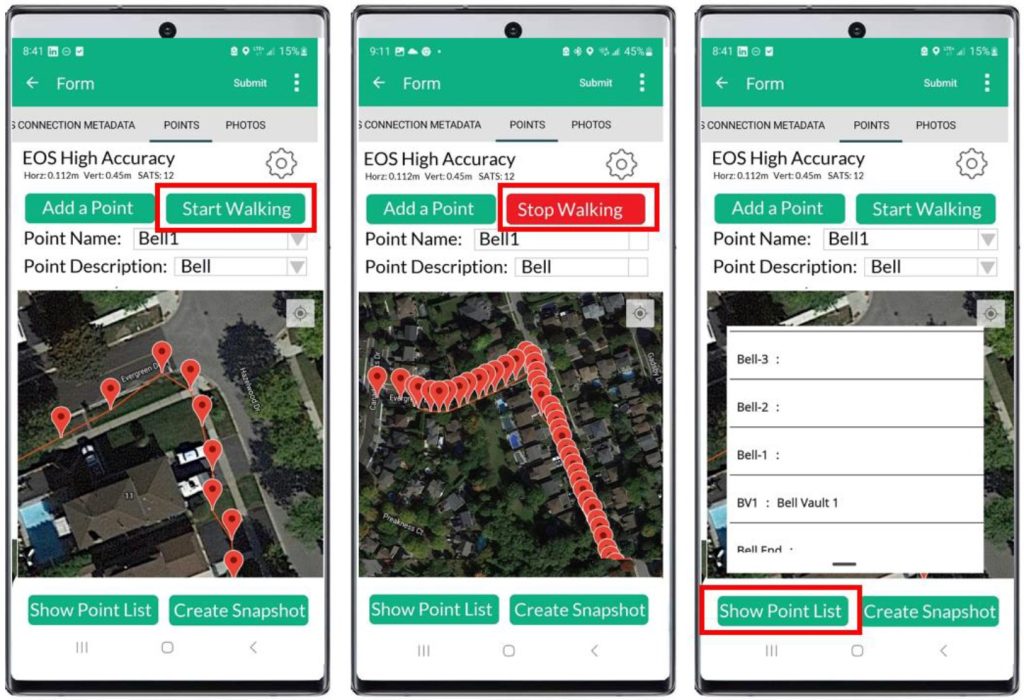

2. GPS Points Sub-table for Utility Feature Points: Implement a Parent Inspection Sub-table (child) named "GPS Points" to collect individual feature points within a broader inspection context. Each point represents a distinct feature, offering a detailed mapping of specific points of interest. By utilizing the GNSS High Accuracy mode, users can ensure that these feature points are accurately positioned, providing a high quality dataset for analysis and visualization. This approach is ideal for scenarios where discrete feature points contribute to the overall inspection data.

3. GPS Points Sub-table for Utility Feature Lines: Extend the capabilities of the Parent Inspection Sub-table "GPS Points" to capture connected feature lines representing linear features or paint locations. Multiple points with the same feature description can be added to map out the trajectory of a feature line. The GNSS High Accuracy mode ensures that these points are precisely located, facilitating the creation of accurate linear representations within the inspection record. In the Azure Map, these feature lines can be themed by color and style, offering a visually intuitive way to interpret and analyze spatial data.

These three data collection options demonstrate the versatility of leveraging GNSS High Accuracy mode across various inspection scenarios, enabling users to capture and visualize accurate spatial information at both point and linear feature levels.

Benefits of Collecting High Accuracy GNSS Inspection Data

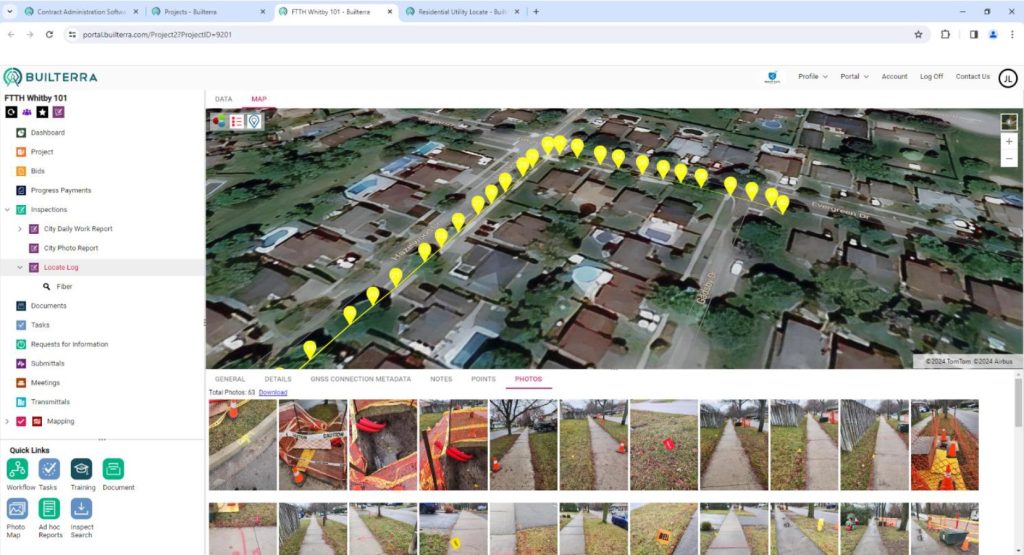

Post-processing the GPS Points table within the AutoCAD environment unlocks several valuable benefits, enhancing the accuracy and practicality of the data collected via mobile phones.

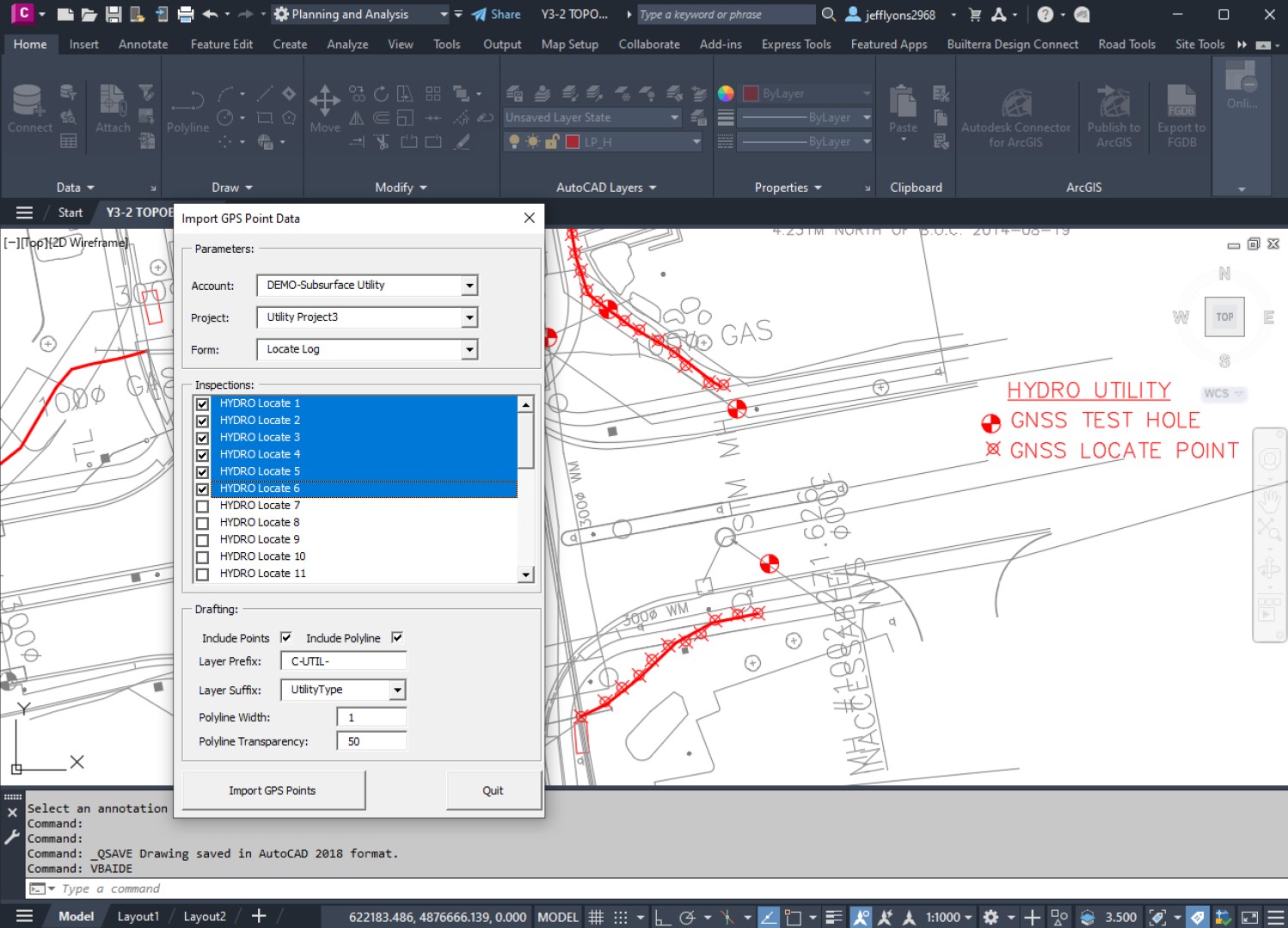

1. Quality Control (QC): The post-processing stage allows for a meticulous comparison between the collected GPS points and historic records or expected locations of existing features (QL-D). Through AutoCAD, users can verify the alignment of data, ensuring that it aligns with established standards and previous records. This quality control step is crucial for maintaining data integrity and reliability, providing confidence in the accuracy of the collected spatial information.

2. Automation in CAD Drafting: Leveraging AutoCAD's drafting capabilities, the collected GPS points can be presented in a visually cohesive and standardized manner. Automation in CAD drafting allows for the seamless integration of collected data into predefined CAD styles and standards. This not only streamlines the reporting process but also ensures consistency in presentation. The use of CAD styles enhances the visual representation of data, making it more accessible and comprehensible for stakeholders involved in the project.

3. Online Repository and Future Reference: Builterra facilitates the creation of an organized and accessible online repository for the collected data. By archiving the processed information, users can easily search and retrieve relevant data for future use. This centralized repository serves as a valuable resource, promoting efficient data management and enabling collaborative decision-making. The structured storage of data within Builterra enhances its long-term usability and ensures that information remains readily available for subsequent projects or analyses.

Conclusion

In summary, post-processing GPS points within the AutoCAD environment not only refines the accuracy of collected data but also brings about significant benefits in quality control, automation of drafting processes, and the establishment of an organized online repository within the Builterra platform. This comprehensive approach enhances the overall efficiency and reliability of spatial data management, contributing to informed decision-making and streamlined workflows in various industries.